There is nothing more permanent than temporary. When managing projects, the project itself may seem small and easily executable. But a week turns into a month, a month into a quarter, deadlines burn, and a small temporary project grows into a monster that consumes time and resources.

We have already reviewed various project management methodologies in previous overviews. You can familiarize yourself with Lean, CPM, Six Sigma, and Prince2.

Today, we will discuss:

- How to estimate and forecast project timelines from scratch in CCPM

- What rules you need to know for accurate time calculation

- Why the Critical Chain Method is the choice of hundreds of successful companies

- How to introduce the Critical Chain Method (CCPM) in your company

- How to implement CCPM using the Worksection service

The Critical Chain Method

Origin of the Methodology

The term “Critical Chain Method” first appeared in E. Goldratt's book "Critical Chain". In previous books by Eliyahu, individual ideas and methodologies were presented that later merged into CCPM: from the "Drum-Buffer-Rope" (DBR) method to the Theory of Constraints (TOC). The latter eventually transformed into one of the most popular project management methodologies.

TOC (Theory of Constraints) is a project and organizational management methodology created by Eliyahu Goldratt. The core of TOC is identifying and managing the key constraint of a system that determines its effectiveness.

DBR (Drum-Buffer-Rope) is a TOC method aimed at "expanding" system constraints, aligning production with the most efficient use of the constraint. It is built on using a work schedule for the constraint (drum), which includes a protective buffer to prevent idle time (buffer), and organizing a mechanism for timely work release into production.

By 1997, Goldratt realized that for the methodology to be implemented in real life, it had to be as simple and understandable as possible. A user-friendly approach, 20 years after the creation of the Theory of Constraints, resulted in its business version — CCPM (Critical Chain Project Management). And as everything new is well-forgotten old, CCPM turned out to be similar to TOC by Goldratt and the PERT method. The latter was developed to calculate the expected duration of project implementation or task completion at certain stages and was used in many organizations in modified forms.

PERT is both a method and a tool for network planning. The method allows estimating task duration based on three evaluations, with subsequent use in diagram construction.

All previous methods developed until the beginning of the second half of the 20th century have become outdated. The Critical Chain Method became the first effective project management method after the development of PERT, which was invented 45 years prior!

The release of four books that popularized the methodology's implementation in business project management did not end CCPM's development. Every year, dozens of project management books appear, utilizing the Critical Chain Method in one way or another (we recommend Lawrence Leach's "Critical Chain Project Management"), and the British company Goldratt, founded by the methodology's creator, offers services for implementing CCPM in project management.

Estimating Project Timelines from Scratch Using CCPM

When starting to work on a project's critical chain (CC), it's impossible to overlook the issue of estimating task durations and the overall project timeline.

Calculating project timelines is harder than it seems at first glance. If you directly ask executors to specify the average time needed to complete a task, they will either provide a time buffer or assure quick completion, putting the entire project at risk.

To avoid this common mistake, consider the following rules:

- Estimate timelines based on 100% executor workload. This will keep all executors on their toes, preventing idle time and significantly reducing the project's overall duration.

- Part of the estimated time should be allocated to buffers — calculate this portion by dividing the total estimated time in half, with the second half becoming the buffer.

- The difference between the average and likely time estimates should be substantial — use a factor of 2x or more (more details on this later). This helps avoid formal distinctions between different types of timelines and is useful when using the PERT method.

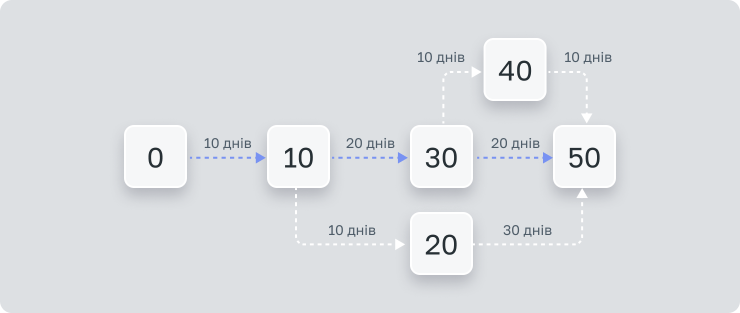

It is convenient to calculate the time required to complete individual tasks and the project's completion using the PERT method. However, determining timelines based on three time values (best, probable, and worst) does not account for potential disruptions and delays. The primary tool for combating these is the project buffer, placed between the completion date of the last task and the project completion date. Thus, the length of the critical chain, and therefore the project timeline, is calculated from the first task (within the CC) to the start of the project buffer.

In addition to the project buffer, it is important to consider the feeding buffer (merging paths buffer) — a time reserve placed between the non-critical chain work stage and the critical chain work stage. The length of such a buffer is usually 50% of the length of the non-critical chain it is added to.

Deciphering PERT as a Method and Diagram

Discussing the Critical Chain Method cannot overlook one of the popular network planning methods — PERT (Program Evaluation and Review Technique).

PERT was first used in 1958 to create the Polaris submarine, building a schedule that included the work of over 3,300 contractors. This highlights PERT's specificity as a network planning method for large projects (typically above 300–400 operations).

According to the method, the duration of each task has boundaries calculated based on statistical distribution.

The key point is that three values are used to estimate the time for each task:

- Optimistic (best)

- Expected (probable)

- Pessimistic (worst)

This inspired the creation of "wave planning." For example, Bas Lansdorp's Mars One project estimated a 22-year duration—from 2011 to 2033. Each stage lasted 1–2 years and was detailed on the project's official website. However, the lack of experience in solving set tasks and the project's uniqueness led to expected timelines shifting. The project's estimated duration increased to 24 years!

Why do you need three values? They are used in a mathematical formula to estimate the weighted average time to complete an operation (project):

tE = (tO + 4tM + tP) / 6

Where:

- tE is the operation (project) time

- tO is the optimistic (best) time

- tM is the expected (probable) time

- tP is the pessimistic (worst) time

As with any calculations, errors are possible here. PERT, by its nature, underestimates the predicted duration of project tasks. Therefore, the more tasks there are, the more errors you may encounter.

For this reason, it is advisable to involve project area experts who can reduce the spread between the three time estimates, thereby reducing the error rate.

PERT Diagram

A PERT diagram represents the tasks necessary to complete an entire project. It consists of elements:

- Arrows that indicate the direction from one task to another and point to events that need to occur

- Numbers assigned to each task for convenient control and tracking

- Days/Weeks/Months specified under each task based on PERT formula results and in the horizontal schedule defining the time within which all project tasks are executed.

How to Create a Working PERT Diagram? Here Are 4 Simple Steps:

- Make a list of stages (large project segments) and tasks within the stages. Write them as project tasks.

- Use the PERT formula to determine the time needed to complete each event. Specify task start and end dates.

- Determine dependencies between tasks to create links. Consider buffer zones.

- Lines in the diagram should lead to tasks linked to the completion of the previous one. Visualize the diagram on paper or a board during team meetings.

Advantages and Disadvantages of the Methodology

Like any other project management method, CCPM has both pros and cons. Whether you use it to achieve company goals depends on the company's format and size, the services or goods provided, corporate culture, and other factors.

So why do companies like American Express, Boeing Commercial Airplanes, Ford Motor Company, and Heineken use the Critical Chain Method in their daily operations?

Advantages of CCPM:

- Balanced Resource Load Over Time: Unlike the critical path method, you are not constrained by a strict sequence of tasks or rigid planning.

- Single Task Per Time Unit: This can be seen as both a plus (no risk of task overlap) and a minus, as it requires executors to quickly switch between tasks and task chains.

- Easy to Identify Delays and Project Deadline Threats: Thanks to buffers (project, resource, time, and feeding buffers), the project manager can "protect" the project completion date from task variations.

- Focus on Critical Tasks: This eliminates competition for resources within the project.

- Eliminates Common Project Issues: Such as "student syndrome," multitasking, and Parkinson's and Murphy's laws.

Disadvantages of CCPM:

- Increased Project Implementation Time: This happens due to time buffers, as the key factor in CCPM is the project completion date, not the individual task completion date. Generally, the longer the project lasts, the higher its cost.

- Higher Requirements for Project Manager Qualifications: Successful CCPM implementation requires more than reading a couple of books; it needs practice and thorough paper-based planning.

- Cumbersome Nature of CCPM in Its "Dry" Form: Creating a CCPM plan involves considering a dozen factors: tasks, timelines, buffers, and more. Even if the project manager handles these complexities, how can they show the management how it actually works? After all, the initial plan will change as the project develops. The main project goal is effective achievement of stated objectives, not merely following the plan.

- Need to Form Separate Teams for Each Project: This arises from the inability to use one resource simultaneously in several different projects. According to Oded Cohen, an international TOC expert, CCPM is more suitable for large projects and enterprises, particularly in the areas of telecommunication network installation, aircraft repair and retrofitting, and developing next-generation wireless technology products.

There are four barriers in any organization's life that all project managers go through or give up, causing the project not to reach the final stage.

- "Student Syndrome": The more time allotted for a task (including buffer), the later the person starts executing it. The desire to postpone task execution until the last minute is explained by procrastination, laziness, and poor management. The latter can be combated by limiting the time for task execution.

- Multitasking: Executing multiple tasks simultaneously usually leads to missed deadlines or deteriorated work quality. According to studies by the University of Utah's Department of Psychology, only 2% of people on Earth can effectively work in multitasking mode. The American Psychological Association noted that constant task switching reduces productivity by 40% compared to sequential task execution.

- Parkinson's Law: Work tends to expand to fill the time available for its completion.

- Murphy's Law: "If anything can go wrong, it will." The subconscious also knows about Murphy's Law, so project participants tend to hedge by reserving time and extending task deadlines multiple times.

Alternative View: Differences Between the Critical Chain Method (CCPM) and the Critical Path Method (CPM)

Key differences between the Critical Chain Method and the Critical Path Method:

- The critical path in CPM is "idealized," while the CCPM path is built considering resource constraints.

- Main tasks of CPM: project planning, determining the most priority tasks; main task of the Critical Chain Method: completing the project as quickly as possible, considering resource constraints.

- The critical path method is focused on predicting project timelines, while CCPM focuses on initial uncertainty in task duration.

- The critical path method is better suited for defining product release timelines, while CCPM is for projects with known deadlines.

- The critical path method is built on a strict task sequence, while the Critical Chain Method is based on flexible planning.

Lawrence Leach, in his book "Critical Chain Project Management," warns against a common mistake. Often managers use the initially built critical chain as the basis for project execution constraints. It is more correct to build a new chain based on the primary chain, considering resource constraints.

The Virtual Critical Chain

By its nature, it is similar to a regular chain. It is important to remain strong under tension. The strength of each chain is determined by the strength of the weakest link. If you hang a multi-ton load on a chain where one link is wood and the rest are strong titanium, it's better to step back: as it will fall in the next second.

The brightest example of how a weak link destroys the entire project is the computer game No Man's Sky. A whole marketing campaign was launched for it, tied to the dates of major gaming exhibitions E3 2014 and 2015. They were strong links in the critical chain "No Man's Sky Release," giving the project high preliminary press ratings and the title of "Best Original Game" and "Best Game from a Third-Party Manufacturer" before release. One of the most important links was creating the design document, and as negative reviews after the product release showed, it was the weakest.No Man's Sky's boring gameplay, lack of original ideas, and cohesive game concept buried the hope for success. Even a powerful marketing campaign, ordering ads in major specialized publications, and decent graphics design did not save the project from complete market failure. So the weak link—design document (a detailed description of the developed computer game, plot, and project essence), the foundation of the gaming project—cracked, and the entire chain fell apart, losing meaning.

The No Man’s Sky example shows that the chain's strength is determined by its weakest links. Real-life rules also apply to a conditional chain: Let the weak link become strong, and the critical chain will become viable. Why is this necessary?

The Theory of Constraints (TOC) comes into play, supporting the Critical Chain Method. One TOC rule is that a project can only progress as much as the weakest link allows. Simply put, start work according to the weakest link's capacity.

In the case of No Man’s Sky, identifying the design document as the weakest element, the developers had two options:

- Redistribute the load and increase resources for creating the design document;

- Reduce resources spent on the marketing campaign and other links that consume most of the resources.

Practical Tips for Using CCPM

The uniqueness of each project cannot be denied: goals, timelines, resources, novelty degree, and company size differ in each specific case, and a single correct, 100% working scheme cannot be created.We offer a comprehensive set of practical steps for using CCPM in individual project planning. It will be useful to you, even if you have already encountered CCPM in project work. If CCPM is new to you, a detailed checklist is provided below. It will help you build a project plan diagram using the Critical Chain Method.

7 Practical Steps:

- Explain to the team working on the project the importance of protecting task duration and resource estimates from management. Unfortunately, chaotic and quick task execution may look impressive but not effective, becoming a real disaster for the project manager.

In Worksection, you can assign permissions to each team member so that only the PM can set deadlines and budget, but they will do so only after agreement and approval with the entire team. - Eliminate resource competition by leveling the workload. This will also eliminate the need to transfer resources between tasks.

You can notice workload unevenness in Worksection in the People tab, where you can see the number of tasks for each specific executor. - Plan tasks that do not depend on other tasks, starting from the project's end date to its start!

In the built-in Gantt chart, you can indicate which tasks are linked and which are independent of others. - To finally resolve the issue of resource unavailability, add resource buffers to the critical chain.

You can use labels to indicate which resources are needed for a task and control the workload in the task list. - Insert a project buffer at the end of the project to accumulate reserve time (about 50% of the entire critical chain length).

Specify it in the project or root task name. You can create a task "Project Final/Completion" and set its start date to the day after all tasks plus the reserve time. This date should also be communicated to customers. - Calculate and set feeding buffers for all paths that affect the critical chains.

This should be done before setting the start and end dates for tasks. - Develop a working scheme to track executor productivity in task work. They should work as quickly as possible and not delay submitting work results after completion.

In the Reports section, you can select the People format and track completed tasks for a selected period.

Checklist Example: Eurovision 2017 and Lockheed Projects

Creating a critical chain project plan from scratch is not easy, but if you have a checklist for choosing the optimal CC path, everything becomes simpler. If you were the organizers of the largest international contest, Eurovision, in Ukraine, what would you need to do according to CCPM?

1. Identify all tasks necessary for project completion.

This includes large blocks (advertising, technical support, security) divided into smaller tasks: advertising (SMM, radio jingles recording, thematic TV show production); technical support (analyzing artist riders, finding and selecting specialists, creating a unified technical network); security (police and National Guard briefing, planning street closure points, organizing metal detector checkpoints).

2. Integrate the formed tasks into a logical chain, indicating the average duration.

If your team is responsible for organizing Eurovision, you have won a state tender and have enough experience to determine the average duration of each task. For example, police and National Guard briefings will take about a week, including conflict situation drills and theoretical lectures, while closing streets for the opening ceremony will take about 8 hours.

3. Specify initial resources — executors, finances, material and technical base. Most companies have a list of specialists they maintain relationships with.

Thus, finding and selecting specialists for the arena's technical support will start with the existing list. Before making a request, update the material, technical, and financial base to understand which specialists, in what quantity, and under what conditions you can involve.

4. Identify possible resource conflicts—fewer resources mean more conflicts during the project's lifespan. Changing task timelines, completely eliminate resource contradictions. The resulting chain of interconnected resources and task timelines will be critical.

Two volunteer coordinators at Eurovision in your team manage 900 volunteers. Each of them often works in two sectors. Poor utilization of such a powerful human resource can lead to confusion and low efficiency. Therefore, it is more logical to set a shift schedule where some volunteers are always free and can be used for urgent or small ongoing tasks, such as preparing souvenir packages for foreign delegations, checking accreditation documents for the press, etc.

5. Work on the chain, shortening its duration as much as possible. This can be achieved by changing task priority and order in the scheme.

You can randomly arrange training sessions for Eurovision volunteers: first aid, evacuation, conversational English course, etc. However, during selection, you already required "English proficiency at least intermediate level." And if not all volunteers will directly communicate with foreign delegations, anyone might need to save a life. Therefore, priority is given to first aid training, making it mandatory, and removing the "mandatory" status from the conversational English course, freeing up 2 days in the critical chain.

6. Add a project buffer at the end of the project's life (up to 50% of the total CCPM duration).

Diverting from Eurovision, the Lockheed company, specializing in civil aviation aircraft creation, decides to launch a new project for an unmanned aerial vehicle for aerial photography in hot spots in the Far East. The project date is quite clear — February 19, 2017. Working out the plan using the Critical Chain Method, you realize you need 1 year and 3 months to launch the test prototype.

Considering possible technological innovations, bureaucratic issues with prototype registration, and the project's novelty in civil aviation, adding a project buffer of 9 months is advisable. As a result, you get a clean 2 years, during which you can confidently provide a working and, most importantly, safe prototype, receiving the necessary certification.

7. Ensure all tasks are needed to achieve the final goal.

Lockheed's policy implies extensive internal work coverage—primarily for company advertising and attractiveness to potential shareholders. However, when developing an unmanned aerial vehicle for military aerial photography, the "Advertising" task block is not needed to achieve the final goal. In the future, when you adapt the device for civilian use, this task block will become relevant. The same applies to design solutions.

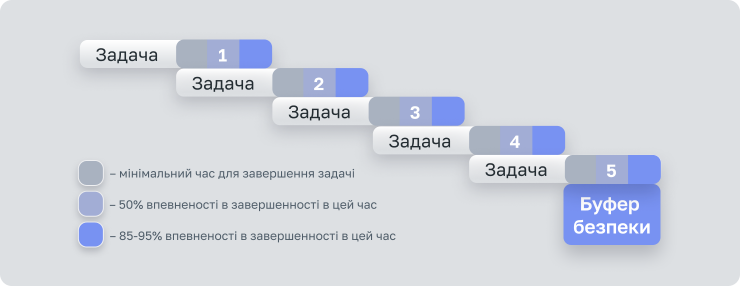

8. Add safety buffers—the same mechanism as in the project buffer, but for individual critical chains, not the entire project. This safety cushion is for managers and teams working on projects with strict deadlines.

Safety Buffer: A visual example of how to save a project from missing deadlines.

Several Lockheed departments participate in UAV development, each responsible for a separate aircraft component. For their tasks within the overall critical chain, the rule from step 6 applies—a safety buffer of 50% of the critical chain length for creating a specific UAV component will protect the project from time problems.

9. Check the critical chain for errors, resource, and time conflicts.

On Habrhabr, an optimal team is considered to be 7 people, plus or minus two employees. What if there are 30, as in Lockheed's UAV project? What if there are more than 1,000, as in the Eurovision preparation project?

Double-checking has never harmed any plan (even if it takes a few days in the critical chain), and the resources it saves by early error detection are immeasurable.

Project Management Plan Using the Critical Chain Method

The project management plan using the Critical Chain Method is the foundation for information exchange, making actions within the critical chain clear not only to the project manager but also to other plan executors.

The project management plan includes:

- A detailed project description: Without understanding the project's specifics, importance, and goals, creating a quality working project management plan is impossible.

- Hierarchical work structure for project execution: For creating an aerial photo and video shooting UAV, the simplified hierarchy is: first, create the UAV concept, then conduct all necessary calculations, and only then build a prototype. Changing the order, the project will never reach its logical end.

- List of responsible for task execution within the hierarchical structure: This includes the project manager, specific company departments, and specialists planned to be involved on a freelance basis.

- Project schedule using the Critical Chain Method.

Large project specifics lead to plan additions. Besides the critical chain (project schedule with leveled resources), they add:

- Separate subject plans for safety, supply, personnel provision, etc. In ISO 21500:2012 International Project Management Standard, they are called "subject groups." In the case of creating a UAV by Lockheed, the procurement subject plan includes processes necessary for acquiring freelance specialist services and UAV control electronic systems and managing interactions with suppliers at the tender level and communication directly after contract signing.

- Recommendations on information exchange in the project, reporting rules, document distribution, and approval: For this, for example, typical reporting forms are created in large enterprises.

- Specifications and standards: In the case of catering preparation for foreign delegations, these can be sanitary and hygienic and anti-epidemic rules and standards for public catering establishments. They are important from both the perspective of catering safety at the reception and compliance with tender conditions based on which the catering was selected.

- Change management plan: Ensures everyone works according to the same project management plan, with the same content and consistent product requirements.

The Project Management Plan Helps Solve the Following Tasks:

- Define direction for project work

- Fix initial conditions and settings that formed the basis of the plan

- Track selection results with different options available

- Establish communication between project participants

- Define criteria for management, the project manager, and participants to control and analyze the project.

Companies Using CCPM Successfully

Successful cases are a must-have for any project management method, determining its future fate. Let's look at the most famous CCPM examples.Riverbank Strengthening Project Against Flooding, Sunagogumi (Japan)

Initially, the project was planned to be completed no earlier than mid-autumn, but by applying CCPM, it was completed two months earlier—in early August. This allowed the Tonebezu River to face the typhoon season fully equipped. Not only thanks to the reinforced banks but also due to established communication with the local population and government about progress.

The company inspired the government to promote a people-oriented project management concept. In 2007, this initiative was launched along with the "Public Works Reform," which, in turn, became a public initiative supported nationally in 2009.

Refrigeration and Air Conditioning Delivery, Danfoss

Danfoss, an international company selling refrigeration chambers and air conditioners in over 100 countries, faced classic management problems: unproductive multitasking, lack of understanding project status and priorities. This led to extended delivery terms that were criticized. Customer loyalty was rapidly declining, and the company had to make decisions.

The choice turned out to be correct. Within two years—from early 2015 to late 2016—Danfoss managed to ensure timely product delivery in 91% of cases. Since 2016, the company received only one customer complaint about delivery problems. In working with the new methodology, Danfoss used project management from Exepron.

Transitioning Projects to a New High Level, Radianz

Creating Radianz, a financial services network, in 2000, management immediately faced team disorganization. Some specialists adhered to risk theory, while others focused on pure product sales. Radianz projects assumed high levels of uncertainty and complexity, requiring an ideal project management methodology for such conditions.

Mark Steven, Business Planning Director at Radianz, identified the following tasks:

- Clear visualization of project status reports for all company projects;

- Ability to plan key resource usage in different projects;

- Ability to track the relationship between project effectiveness and its success reasons, to understand further development and improvement paths.

In the first stage, the method was used in two pilot projects, in the second—six more projects were added, and by autumn 2002, the Critical Chain Method was used in the simultaneous launch of 35 projects.

As a result:

- Project efficiency increased by 50%;

- Clear visual reporting of the company's and individual projects' activities emerged;

- It became possible to trace the connection between project success and failures and their causes;

- Various statistics formation, helping to improve the company's performance.

Programs and Extensions

Software working on the Critical Chain algorithm greatly facilitates project managers' and task executors' work within projects.

Before using applications or extensions, it will be useful to master building the critical chain the old-fashioned way—manually. Firstly, you will better understand how to apply various specialized software functions and what it provides for chain construction, and secondly, you will understand where unexpected results from using programs came from.

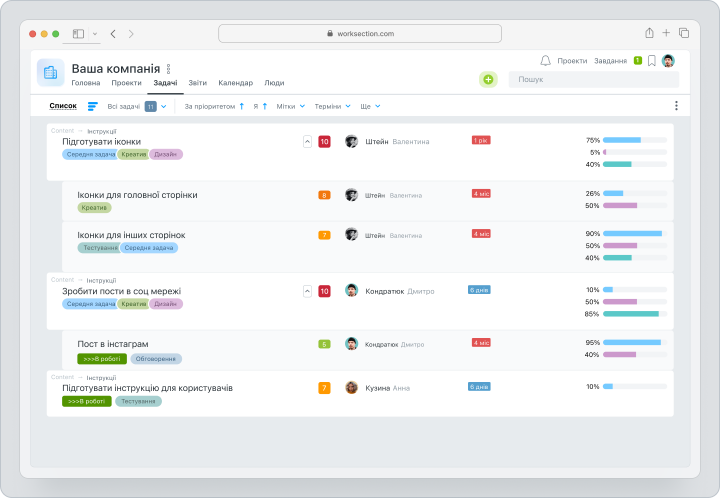

Worksection

Worksection is a Ukrainian cloud service for project management and team collaboration using the Critical Chain Method. Very convenient for digital and design agencies.

For CCPM, it offers:

- Control of task loading for each team member (filter by people), avoiding downtime and colleague overload.

- Building chronological links between tasks through a Gantt chart.

- Setting deadlines considering safety buffers.

- Task priorities.

- Convenient calculation of resources spent on a task: time, money, employees.

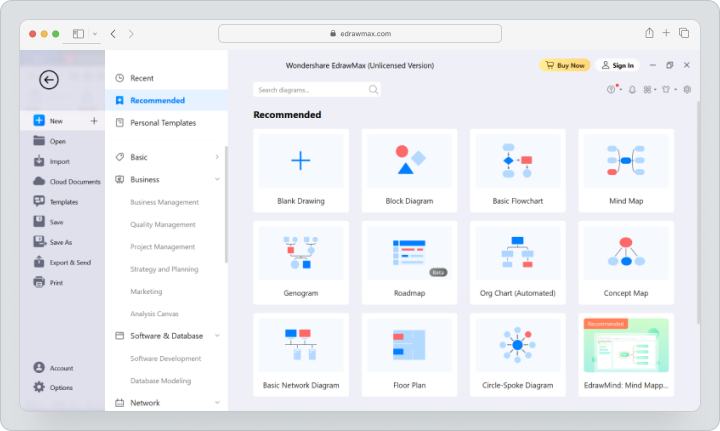

Edrow Max

With Edrow Max, you can create diagrams not only using the Critical Chain Method but also the Critical Path Method—drawing "from scratch" or using built-in templates.

Verdict

Each project is characterized by specific parameters: goal, duration, resources, novelty degree. But the main task is proper planning: setting goals, defining resources—both human and material, organizing project tasks.

The Critical Chain Method is designed for managing large projects, whose executor number and format do not guarantee 100% timely project completion. By determining task priorities, distributing resources, and adding time buffers, CCPM significantly reduces the final time and resource costs of project implementation.